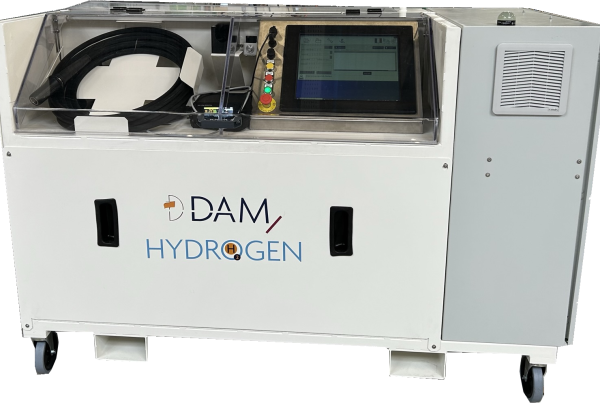

Leak test bench for high-pressure hydrogen piping systems

Home »

Description

DAM Group designs standard and customized high-pressure test benches for leak-testing piping systems and fuel cells for all mobility sectors: rail, automotive, marine, etc.

This technology is adaptable to all types of piping: H2 tanks, valves, piping, hoses, fittings, etc.

Leak tests are carried out with ramp up to 875 bar. This gradual pressure build-up makes testing safer and more reliable.

These test benches enable us to collect data on the quality, reliability and performance of the component under test. The modularity of our installations makes it quick and easy to adapt to future product developments.

DESCRIPTION

- Leak test of H2 piping at 875 bar

- Mobile micro-leak detection device

- H2 tank purging

- Compatible with H2 high-pressure quick connections

- Validation of tightness and pressure resistance

- Progressive leak detection

- Detailed production test report

- Installation safety: use of 95% N2 – 5% H2 forming gas

- Product safety: gradual pressure increase

- Safe test procedure

Measurements :

- Pressure test: 875 bar

- Forming gas: 95% N2 – 5% H2

- Leak ratio detection: 10Ncm3/h

Applications:

- Developed for the assembly of hydrogen components

- Adaptable to all hydrogen piping systems: H2 tanks, valves, piping, hoses, fittings

- Trains / Automotive / Maritime

- Software configurable by user

- Data archiving and traceability

- Direct display of leak test values

- Display of test history

- Data communication: Ethernet; Modbus TCP/IP

- H2 purge

- Infrared link: SAE J2799 protocol

LET’S EXPLORE THE RANGE OF POSSIBILITIES TOGETHER

WE MEET YOUR MOST SPECIFIC NEEDS

ACHIEVEMENTS