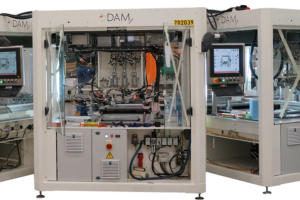

DG 10 030 - Leak test bench for cylinder head, engine block, crankcase (e-motor, transmission, battery, EDU)

DESCRIPTION

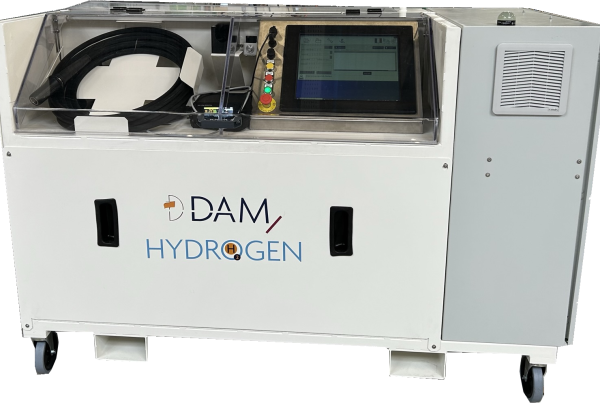

DAM Group has developed and designed a range of standard and innovative leak test machines that are at the heart of Industry 4.0.

The innovation of these leak test machines lies in their adaptability and connectivity features.

Indeed, thanks to the interchangeable and intelligent tooling, manufacturers gain in flexibility and competitiveness.

Flexible and modular, these machines can easily be integrated into a robotized island or a production line.

The products that can be tested on this sealing machine are cylinder heads, engine blocks, casings (e-motors, batteries, EDU, transmission, oil, etc.).

The DG 10 030 is the high capacity machine (press force: 4000 DaN) of the range.

DESCRIPTION

- Integrated database for result storage and advanced supervision

- Create, save and deploy your test sequence

- Manage and track your production

- Interchangeable tooling

- Open interfaces, 4.0 Industry

- Reduced time to market

- Optimized cycle time

- Intended for Laboratory and Production

Measure :

- Automatic tooling adaptation

- Sequence data : XLM (sequence >100)

- Internal database : >10000 results

- Raw data : 50 tdms

- Open connection

Data communication :

- Industrial protocol : EthernetIP /Modbus/ Ethernet

- Web service API accessible by web service

- External database MySQL/MsSQL/ Other

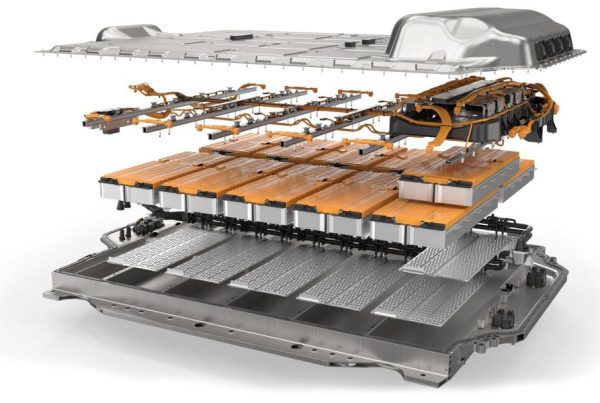

Tested product :

- Maximum size of the DUT : 600 x 400 x 400 mm

- Clamping forces : 3000 DaN

- Number of pneumatic circuits (clamp or switch): optional

- DUT Loading: Manual / Robot/Cobot/Conveyor

- Products tested: cylinder heads, engine blocks, crankcase (e-motors, batteries, EDU, transmission, oil, etc.).

Options :

- DAM measurement cell

- R&R generation tools

- Marking / Rotary plate

- Additional measuring cell

- Automatically calibrated leakage

- DAM Data Management

- Pressure test range

OUR REFERENCES

LET’S EXPLORE THE RANGE OF POSSIBILITIES TOGETHER

WE MEET YOUR MOST SPECIFIC NEEDS

ACHIEVEMENTS