Robot island for cylender head leak test

DESCRIPTION

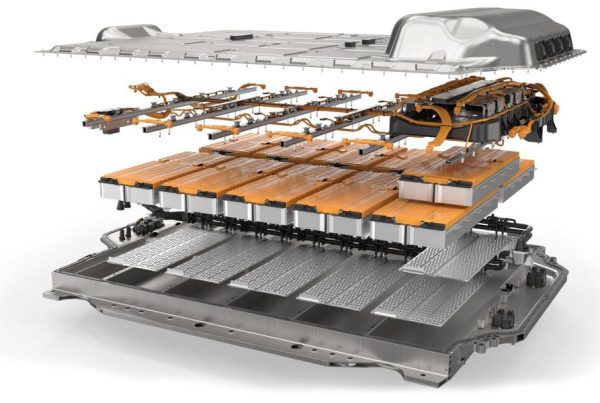

Our client specialises in automotive engine and chassis parts, and designs, develops and produces aluminium castings and machined parts for a wide range of automotive manufacturers and tier 1 sub-contractors.

The products to be tested are the R3 and R4 cylinder heads that equip Mercedes (A-Class) and Renault/Nissan (Captur and Senic) engines. The engine is referred to as HR13 DDT (Renault/Nissan) and M282 (Mercedes).

The project

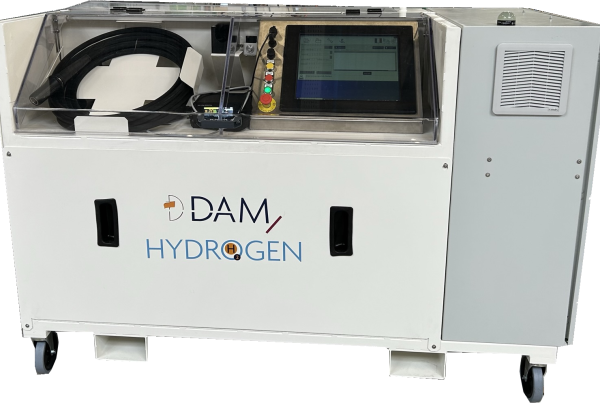

DAM therefore had to develop a robot island to check these two types of cylinder heads for tightness, but also on a fakir station (to check the presence of holes) and finally carry out laser marking with camera reading. In order to respect the cycle time of 32 seconds per part, we have implemented 2 leak test bench.

Watch the video of the robotic island

DESCRIPTION

Our customer already had a line to control this type of cylinder heads, but with only one in-line conveyor and therefore without a robot.

The special feature of this cylinder head is its triangular shape, for which we had to adapt the robot’s gripper, a double gripper, without damaging the machined surfaces of the cylinder head.

LET’S EXPLORE THE RANGE OF POSSIBILITIES TOGETHER

WE MEET YOUR MOST SPECIFIC NEEDS

ACHIEVEMENTS